|

| Finally some solar panels on our roof in Norway. |

For so long I have had a dream to get some solar panels on our roof at Kolsås in Norway. We have no incentives for this in Norway as of 2014, but I decided to check out the cost of a small installation . Someone has to start the solar revolution here too.

It turned out that I could get the 250Wp 1 x 1.6m solar panels for NOK 2500,- each from

Norsk-Solenergi AS which was down NOK 1000,- from the best price found a year before.

|

| 250W Micro-inverter from Power-One |

Also I have learned that small installations now can be done using micro-inverters.

Enphase,

SMA, and

Power-One ABB are some of the bigger companies making them. One solar panel connects to one micro-inverter and forms a micro power plant when connecting it to the 230VAC in your house. This is a grid-tied system. The other alternative is a single string inverter. The problem with them is that you might need as many as 10 solar panels in a string to get to the minimum working voltage of 300VDC. I decided on the Power-One Aurora micro-inverts, mostly based on the fact that I have used other Power-One products before. There is no place to buy micro-inverters what so ever in Norway just yet. But I managed to locate seven different web-shops in Europe that had them in stock. I mailed them all. Only

CCL in the UK was interested in shipping anything to Norway! Well, at least it made the choice of selecting a supplier easy... Two weeks later I had all the components needed after spending a total of NOK 18.300,- for this 1kWp installation.

|

| Planning the Trunk-Bus cable layout prior to installation. |

|

| Each solar panel is a power plant. |

The + and - DC connection from the solar pannel connectes directly to the micro-inverter. The output is 230VAC that connects to the Trunk-Bus that will connect up to four panels. (It can be expanded with another Trunk-Bus cable for a total of 31 units). No electrican is needed for this part, as it is just snapping cables together. The end of the Trunk-Bus is 230VAC and can be connected basically anywhere to the 230VAC of the house through a normal on/off switch.

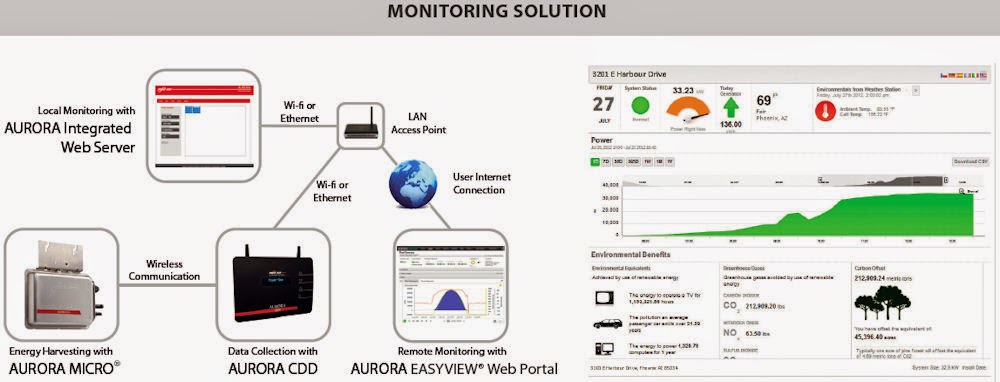

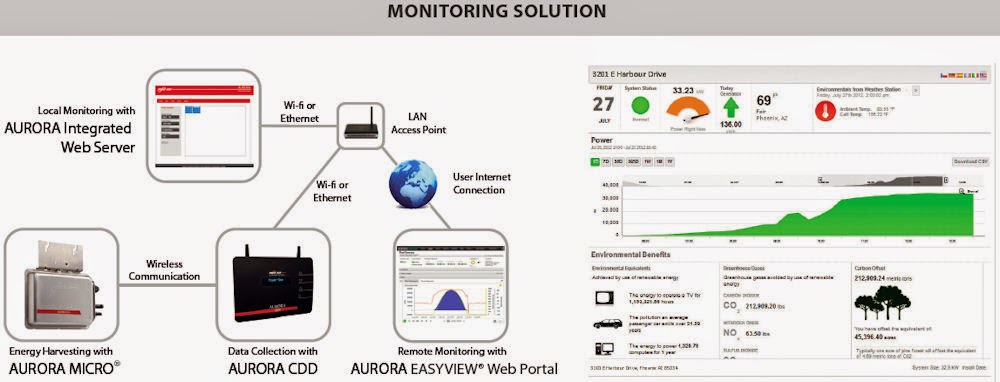

In order to use the micro-inverters you also need a Power-One CDD (Concentrator Data Device) foreach installation. The integrated web server is used for setting up the installation and for detailed monitoring of each micro-inverter, such as temperature and status.

|

| This is how the system connects together for setup and monitoring. |

The CDD collects data from each micro-inverter and connects to the web interface for displaying it. Anyone with the link can view our solar production:

Medhus residence solar production live The panels are mounted at SE at 14 degrees angle up from horizontal.

This time-laps video of the rising morning sun shows one of the benefits of micro-inverters.We have a street light right outside our house, and you can see the shadow of it moving across the solar panels from about 8am to10 am.

|

| Only panels that are in the shade of the light pole have a lower output. Others are at full production. (From the web interface) |

By looking at the web interface you can "see" the same shadow as changes in the power output on each panel (modules). The panels with no shade has full production, while the ones with shade have about half. If the panels were connected to a traditional string inverter, all panels would have been restricted to the one with the lowest output for a total of only 4x40W= 160W in stead of 308W as here.

|

| Getting a free pluss-minus meter |

We had a meter from 1977 and needed a new one that can measure current flowing in both direction. Hafslund Nett came on a few days notice and installed one for free. The lady that showed up was great. She juste LOVED to install meters. Could not wait until the huge roll out of new meters that shall be completed by 2017.Then everyone in Norway will be ready for solar metering. Hafslund Nett is ready for new solar customers with gried-tie feed in, but many other places in Norway you should not expect this yet.

Our local paper had a story on our installation in July 2014

which is also on the web as

Krafttak gir el-overskudd (Norwegian) together with

Vil ha 40% investeringsstøtte på solstrøm (Norwegian only).